If you would like to get in touch with me, please feel free to reach out via email or phone.

Email: Bert.Langan@gmail.com

Phone: 952.200.3660

I’m a hands-on problem solver with a strong background in scientific glassblowing, Android app development, and process improvement. I enjoy tackling complex challenges, whether it’s crafting precision glassware for scientific applications, developing digital tools to streamline workflows, or refining production methods to boost efficiency. With years of experience working in both creative and technical fields, I’ve learned how to balance precision with innovation, ensuring that every project meets high-quality standards while staying practical and cost-effective.

Beyond technical work, I take pride in training and mentoring others. Teaching apprentices and glassblowers has been one of the most rewarding parts of my career, helping them build confidence and refine their skills. I’ve also worked closely with teams to scale production, maintain strict safety protocols, and introduce quality control measures that keep products reliable. Whether it’s leading a team, troubleshooting an issue, or improving a system, I believe that collaboration and clear communication are key to making any process more effective.

I thrive in fast-paced environments where adaptability and creative thinking are essential. Managing large-scale projects, handling custom client requests, and ensuring smooth operations—especially in high-demand situations—has given me a strong ability to balance big-picture goals with the finer details. I’m always looking for ways to improve efficiency, strengthen relationships with clients and partners, and create solutions that make a meaningful impact.

Denver, CO • 952.200.3660 • Bert.Langan@gmail.com

Technically-inclined professional with extensive experience in designing and implementing solutions across scientific glassblowing, Android application development, and operational efficiency.

Senior Scientific Glassblower | Aug 2019 – Present

Owner | Oct 2012 – Aug 2019

Visit the projects section of this site to see how I apply my skills to real-world challenges. Highlights include:

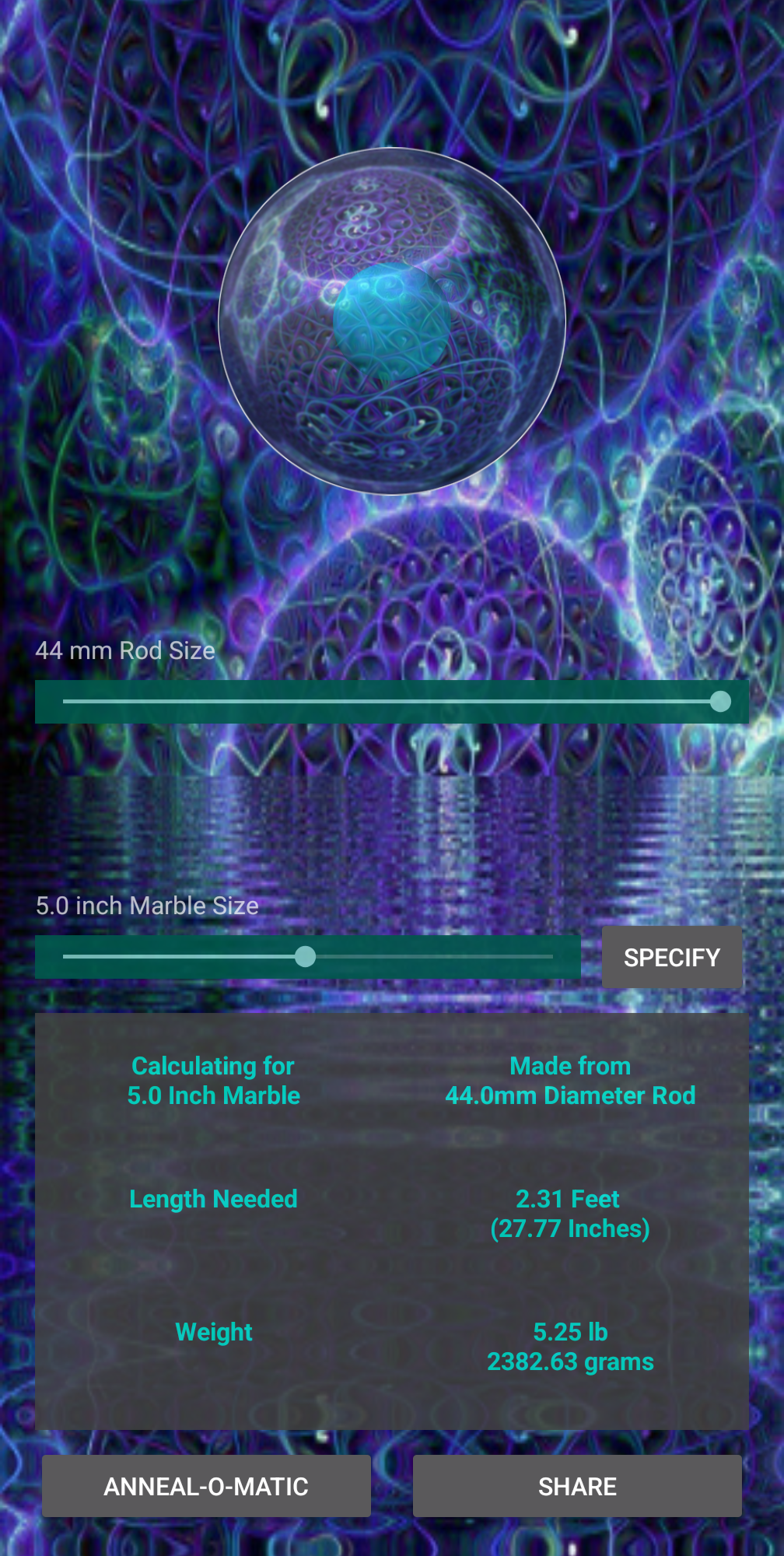

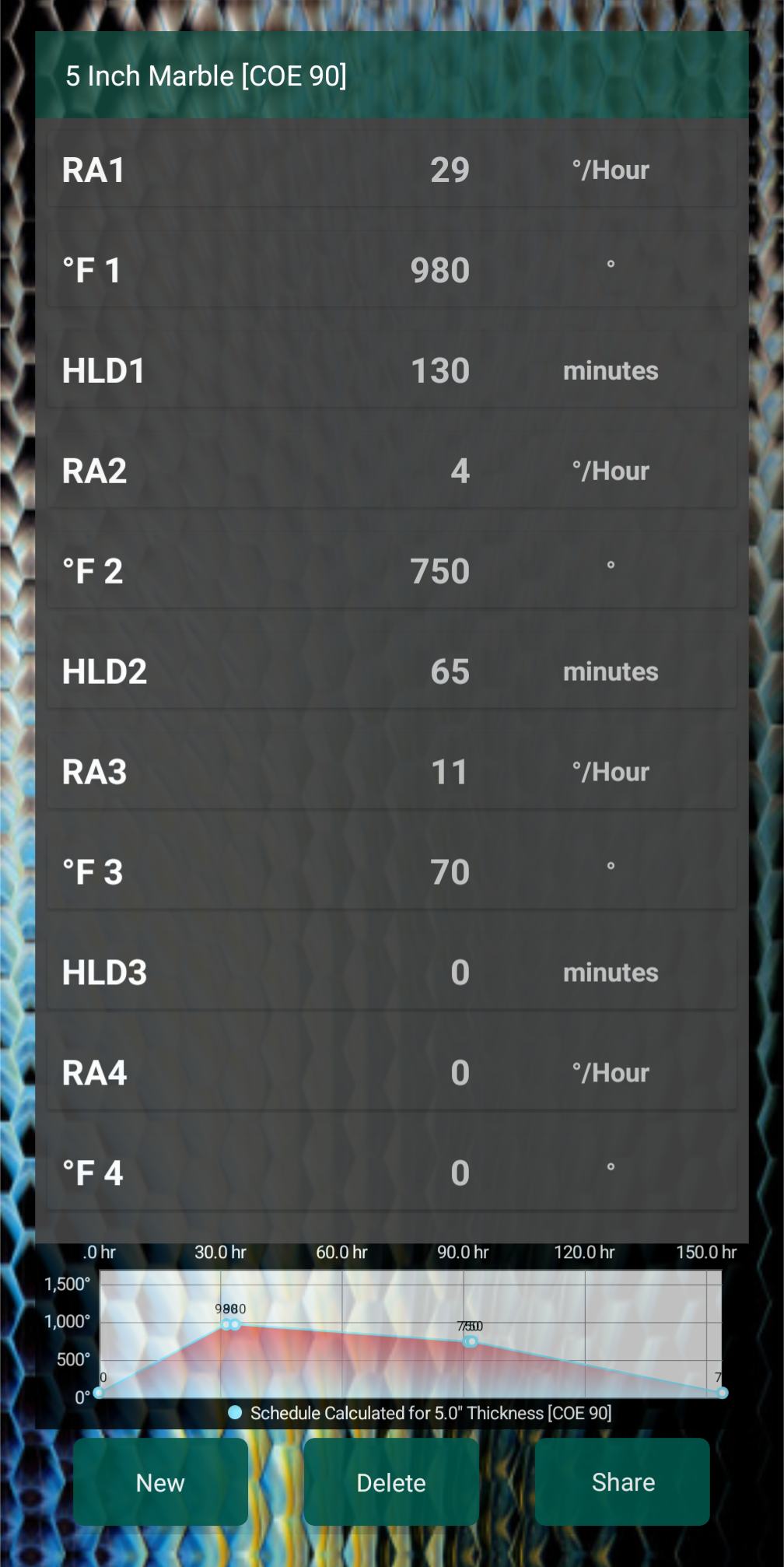

The goal of Glassblower's Toolchest is to empower artists to push through their perceived scale limitations, and to preserve their work for future generations to enjoy. It does this by accurately calculating electronic annealing schedules for kilns and providing precise calculations for the required glass amount for work at the desired scale.

Some of the functionality has been converted to a web interface, and can be accessed at:

Marble Calculator

Glass Annealing Schedule Calculator

The original project, and APK can be found over at Github

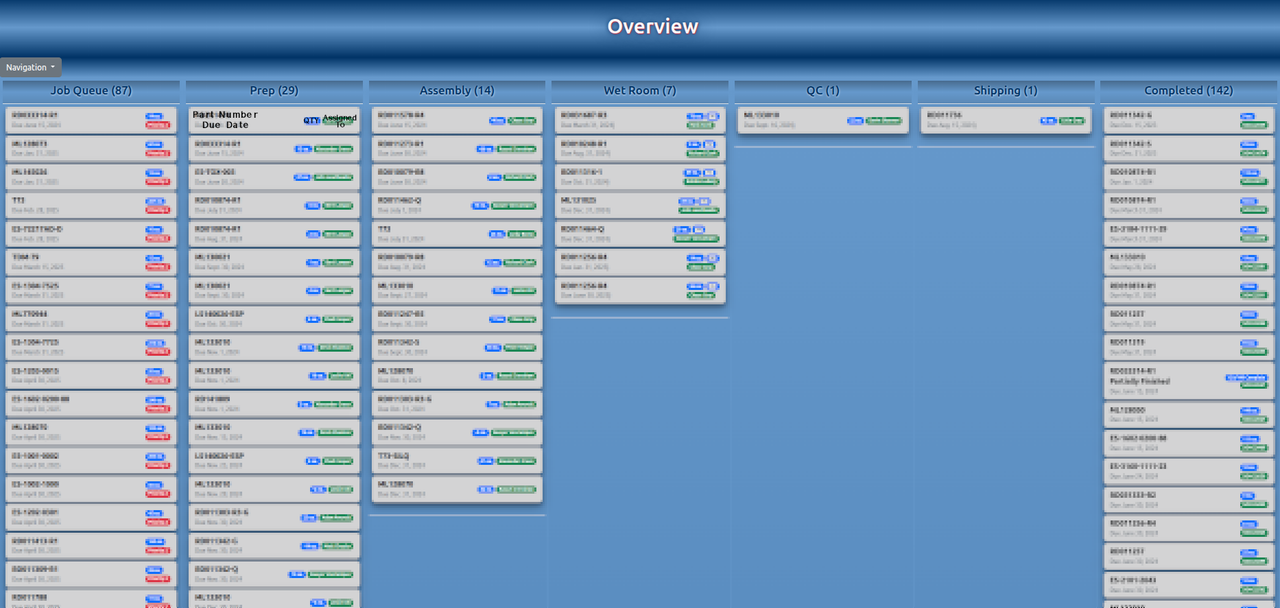

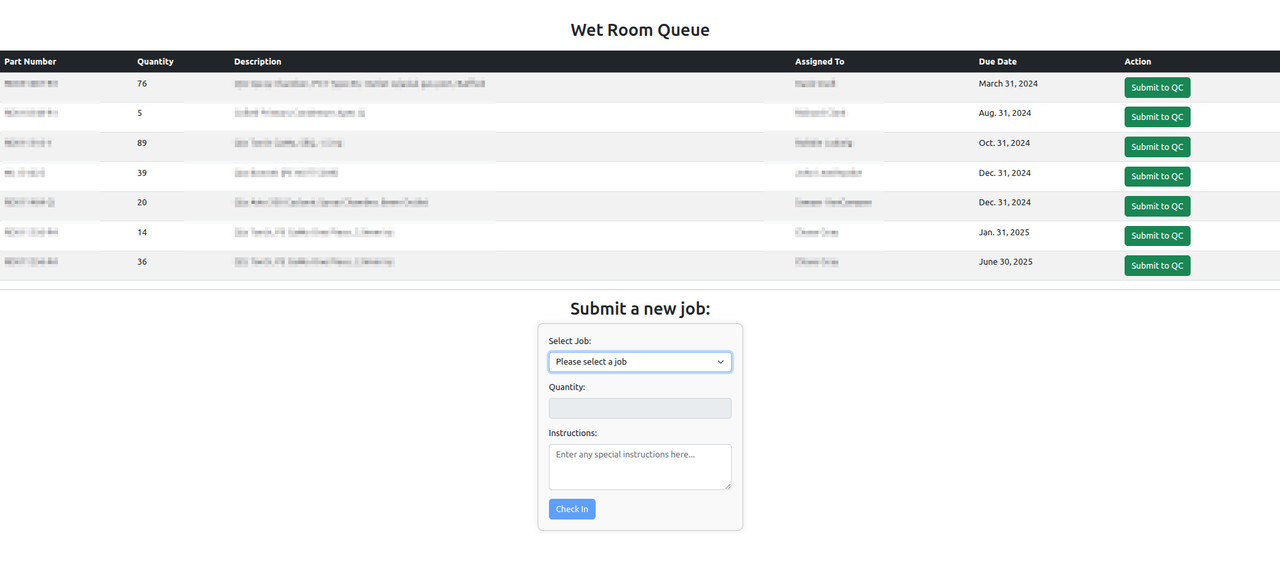

SpectraCadence imports orders from QuickBooks and organizes them as jobs on a KanBan board.

Jobs automatically move through the steps on the KanBan board, triggered by the physical change of hands. The result is a streamlined production process, and optimized efficiency.

The administrative program provides key insights to where each job is in the process, the workload of any given employee, and a powerful real-time view of where the shop is in regards to monthly production goals.

Modular steps can easily be customized, added, or removed from the production process. Each step shows up as a column on the kanban.

Each job, employee, and part number has a comprehensive history which shows up as an interactive timeline. Timeline events are created when a job passes from one column to the next.

If you would like to get in touch with me, please feel free to reach out via email or phone.

Email: Bert.Langan@gmail.com

Phone: 952.200.3660